ABOUT US

Our Company TRUCKER SUBFORNITURE S.r.l was born in 2008 as a branch of Fasern S.r.l. . In Trucker, we have an ultra-thirty years of experience in the production of composite material components (manufactured with resins and fibers such as glass, carbon, Kevlar ®, etc) with productions in various sectors (automotive, nautical, agricultural, etc.). Its 5,500 square meters of covered surface offers the possibility to manufacture composite materials of various sizes and production volumes, utilizing technologies that allow production for medium and large series users, unlike traditional systems suitable only for small series production.

From design to mold construction, from molding to finishing

PRODUCTION TECHNOLOGIES

WET MOLDING

Wet Molding: stampaggio RTM a compressione

SMC

Sheet Molding Compound: materiali compositi rinforzati con fibre di vetro o carbonio in lastre per stampaggio a compressione

BMC

Bulk Molding Compound: materiali compositi rinforzati con fibre di vetro o carbonio in massa omogenea per stampaggio a compressione e iniezione

RTM

Resin Transfer Molding: stampaggio ad iniezione di resina

VARTM

Vacuum Assisted Resin Transfer Molding: stampaggio di resina assistita da vuoto

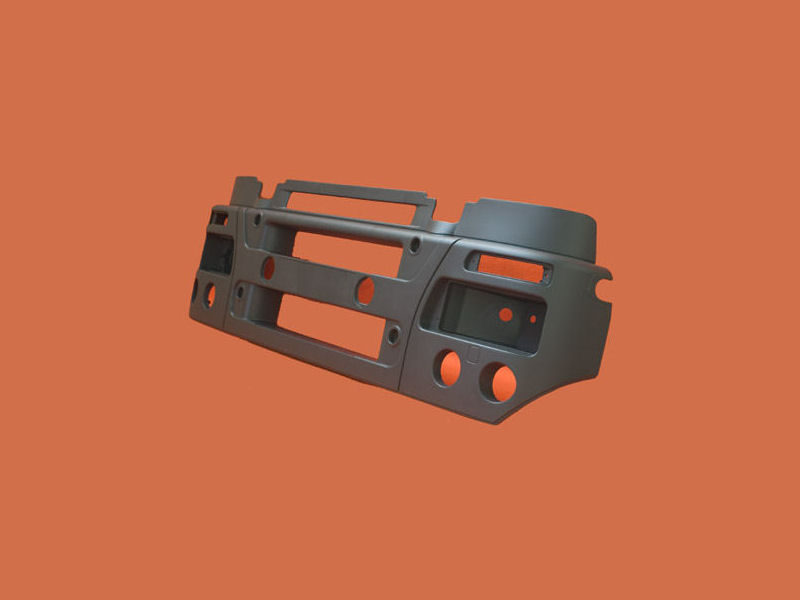

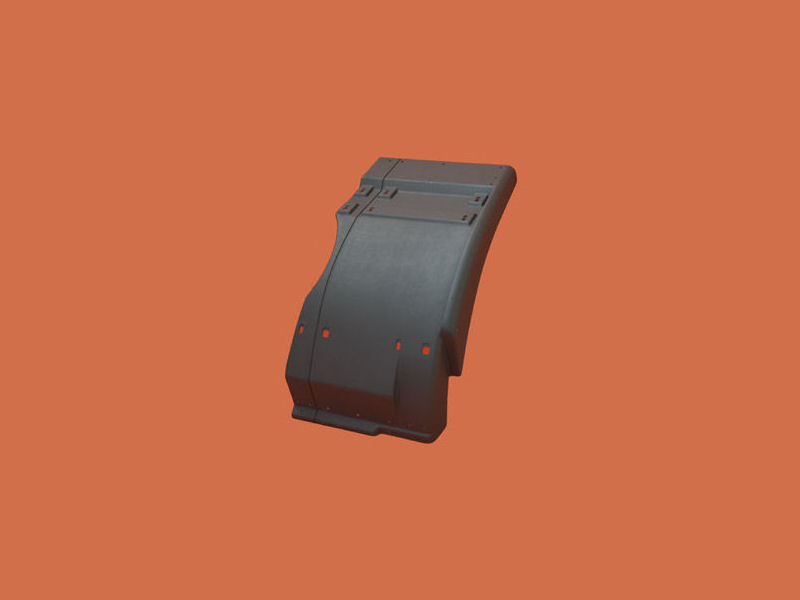

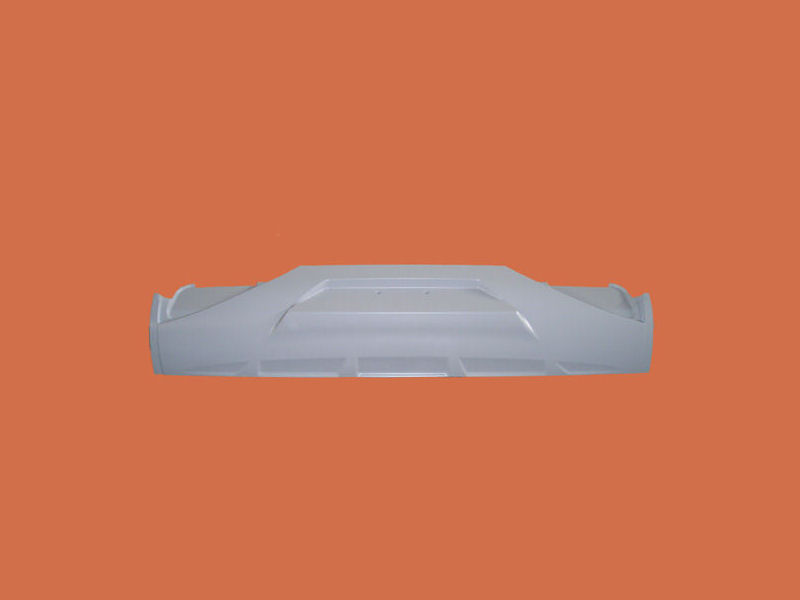

OUR PRODUCTION

WET compression molding

Sheet Molding Compound – SMC

Bulk Molding Compounds (BMC)

Resin Transfer Molding ( RTM )

Vacuum Assisted Resin Transfer Molding Process (VARTM)

Vacuum Assisted Resin Injection ( VARI )

Fiberglass Compression Molding

Carbon Compression Molding

kevlar Compression Molding

Poly Ester resin molding

Vinyl Ester Resin Molding

Epoxy resin molding

APPLICATIONS